Flexography

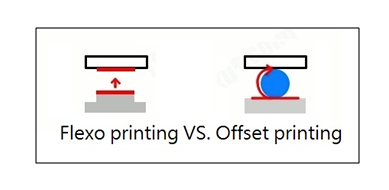

As we indicated in

previous article (Offset printing), flexography (= flexo printing) is direct

printing transferring the ink from the plate to the paper on roll other than

offset. Following are the main features of flexo printing.

Flexography

requires the product of so-called printing plates. Regarding printing plate,

with its slightly raised image and letterpress, is rotated on a cylinder and coated

by fast drying ink. Ink applied to the printing area, which is then pressed

against the paper so it transfers. Therefore flexo printing is also known as

“surface printing”, is a relief printing method that the image to be printed is

higher than the background (See below picture).

Flexography

compared with offset printing, it uses water-based inks are solvent-free, not

only quick-drying but also more environmentally friendly. However, drying of

water-based inks is extremely affected by the surrounding environment. When the

weather is humid, printing sheets are easily affected with damp. When it comes

to rain or splashing by water, the surface of printed image may easily reprint

to other objects.

The main difference

with both processes is that offset printing is only done on flat and smooth surface

while flexo printing can be used on a wider range almost any substrate with a

flexible surface. For example, it can be applied to corrugated cardboard, paper,

cellophane, plastic and fabric. By using different machines provides a clear

impression image on diverse materials. While offset printing is

well-suited for short-run work, flexography provides more economical production.

What are Advantages

of Flexo Printing:

·

Runs at high press speeds

·

Economical, with high-visibility graphics when it requires the use of

only a few colors.

·

Printed material range is more widely than other printing processes.

·

Lower investment costs for printing related equipment and maintenance.

·

Water-based printing ink is more environmentally friendly.

If you would

like to know Syncmen more, you can look up the websites as below:

Visit Taiwan

Trade: https://syncmen.en.taiwantrade.com/

Our Web:

http://www.syncmen.com.tw/